Port Crane NDT Inspection

December 03,2025

Port cranes are the lifeline of every port. They operate continuously under extreme load cycles, harsh weather conditions, and corrosive marine environments. Even a minor defect in these high-tonnage machines can lead to major breakdowns, safety risks, and costly downtime. This is where Non-Destructive Testing (NDT) becomes a vital part of crane maintenance.

At PORTECH Engineering Pvt. Ltd. we provide advanced Port Crane NDT Inspection services that help ports maintain safe, reliable, and efficient crane operations while ensuring compliance with international standards.

Why Port Crane NDT Inspection is Important

Port cranes such as STS, RTG, RMG, MHC, and Yard Cranes are subjected to continuous stress. Over time, the metal structures, weld joints, mechanical components, and ropes start developing hidden defects such as:

• Fatigue cracks

• Corrosion thinning

• Internal weld flaws

• Rope strand breaks

• Misalignments

• Material degradation

NDT allows these issues to be detected early without dismantling the crane. Early detection reduces repair cost, prevents safety hazards, and keeps port operations running smoothly.

Critical Areas Inspected During Port Crane NDT

PORTECH follows a structured inspection approach covering all high-risk areas:

Structural Components

• Boom & jib

• Mast & gantry legs

• Tie rods & A-frame

• Platforms & ladders

Weld Zones

These sections bear the most stress and are prone to fatigue failure.

Mechanical Parts

• Wire ropes

• Sheaves

• Drums

• Hooks

• Bearings

Load-Bearing Points

• Slew bearings

• Boom hinges

• Rope anchor points

• Trolley rails

Every inspection is documented with images, measurements, and defect mapping.

PORTECH’s Step-by-Step NDT Inspection Process

1. Pre-Inspection Planning

Our engineers study crane history, failure records, load cycles, and maintenance logs to identify high-risk zones.

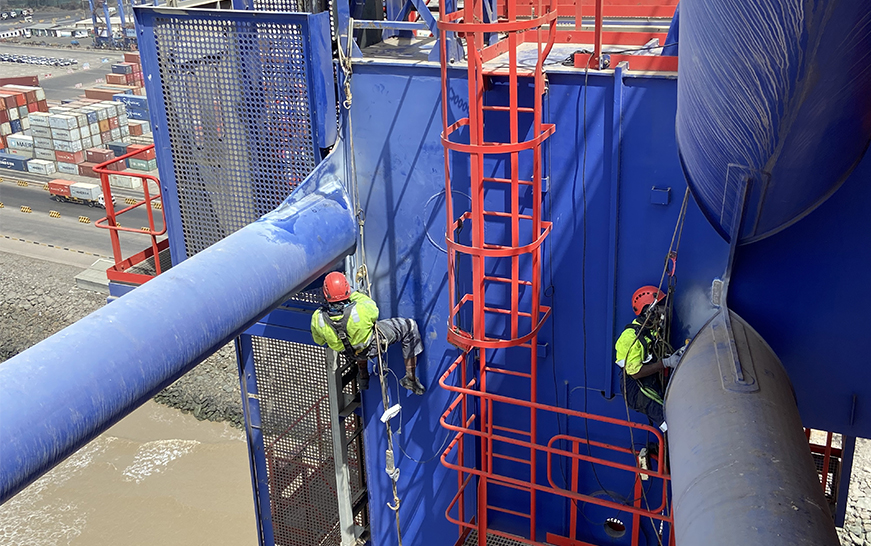

2. Safe Access Planning

We use MEWPs, rope access, and drone surveys to ensure safe inspection at height.

3. On-Site Testing

Certified Level II & Level III technicians carry out detailed UT, MT, PT, RT, and other required NDT methods.

4. Data Interpretation

All readings and images are analyzed digitally to compare trends and detect potential deterioration.

5. Reporting & Recommendations

The final report includes:

• Defect location mapping

• Severity level

• Repair priority list

• Remaining useful life analysis

6. Post-Repair Verification

After repairs, PORTECH re-checks the crane to ensure it is fully safe and fit for operation.

Common Issues Identified During Port Crane NDT

• Fatigue cracks near boom-to-mast joints

• Corrosion in boom chords and gantry legs

• Weld cracks at brackets and connections

• Misalignment in trolley rails

• Internal wire rope breakage

• Sheave and drum wear

• Slew bearing looseness

Early detection avoids unplanned shutdowns and protects expensive machinery.

Why Choose PORTECH Engineering Pvt. Ltd.?

• Specialized in Port Crane Inspection & Repair

• Level II & III certified NDT professionals

• Latest instruments and digital testing tools

• Decades of crane maintenance experience

• Detailed reports with clear action plans

• Fast response and onsite support

PORTECH is known as the “Best Port Crane Doctor” trusted by ports for reliable, precise, and safe crane inspection services.

Conclusion

Regular Port Crane NDT Inspection is essential to ensure smooth port operations, extended crane life, and the safety of workers. With PORTECH Engineering Pvt. Ltd.’s advanced NDT solutions, ports can move confidently toward predictive maintenance and maximum crane performance.