About the client:

World Crane Services (WCS), founded in 2002 in Dubai’s Jebel Ali Free Zone, is a global leader in the port and terminal industry. With deep operational expertise, WCS designs durable engineered products such as safety cages, terminal trailers, and custom port equipment. The company is widely known for its commitment to reliability, durability, and engineering excellence across international ports.

Project Overview:

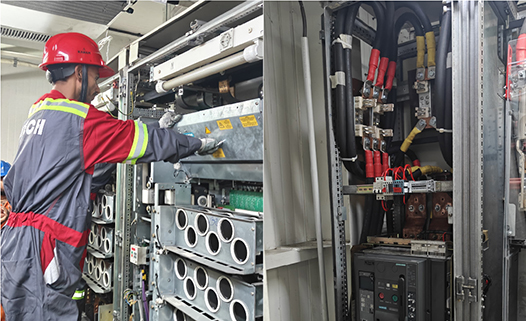

PORTECH was entrusted with executing a Quay Crane (QC) Drive Refurbishment project aimed at enhancing crane reliability and reducing operational downtime. The scope involved the complete replacement and refurbishment of the crane drive system, carried out within a tightly controlled shutdown window to minimize disruption to ongoing port operations. Given the critical nature of quay cranes in terminal productivity, the project demanded precision execution, strict adherence to safety standards, and flawless coordination to ensure timely handover back to operations.

Key Challenges:

The project presented multiple operational and logistical challenges, including:

Tight Shutdown Window: The refurbishment had to be completed within a limited timeframe due to continuous port activities.

Heavy Component Handling: Safe dismantling and installation of large drive components required meticulous lifting plans and certified equipment.

24×7 Shift Operations: Round-the-clock execution was necessary to meet the project deadline.

Safety-Critical Environment: Strict compliance with MSRA, LOTO, and OEM standards was mandatory to ensure zero incidents.

Despite these complexities, PORTECH maintained a strong focus on safety, quality, and schedule adherence throughout the project lifecycle.

Solutions Implemented

PORTECH adopted a well-structured planning and execution strategy to successfully deliver the project within the stipulated timeframe:

Detailed Scheduling & Planning:

A comprehensive execution plan was developed, breaking down activities into clearly sequenced tasks to optimize time utilization during the shutdown period.

OEM-Compliant Refurbishment:

The QC drive refurbishment was carried out using OEM-certified components, ensuring compatibility, performance reliability, and long-term operational efficiency.

Precision Installation & Alignment:

Advanced alignment tools were used to install and align the refurbished drive strictly as per OEM specifications, ensuring smooth crane operation.

Strict Safety Protocols:

All activities were executed under MSRA and LOTO procedures, supported by certified lifting equipment, predefined lifting paths, and continuous safety supervision

Efficient Execution & Skilled Manpower:

Experienced technicians worked in 24×7 shifts, enabling seamless execution and completion within the terminal’s narrow shutdown window.

Quality Assurance & Commissioning:

The project concluded with thorough electrical checks, load testing, parameter configuration, and detailed commissioning documentation to validate system performance.

The results achieved:

QC's Drive replacement work is completed successfully.

Client Testimony

“Excellent team support from your team and really appreciate the way the team responded on site, which enabled us to handover the crane back to operations in 7 days. This is really a great achievement; I would like to take this opportunity to thank each and every member of the participated team of the refurbishment and my personal congratulations to each one of them for all the efforts made.”

— World Crane Services (WCS)